A 3-phase motor starter wiring diagram is essential for controlling and protecting induction motors. It provides a clear visual guide for connecting components like contactors, overload relays, and circuit breakers. These diagrams ensure safe and efficient motor operation, covering direct-on-line (DOL) and star-delta configurations. Proper wiring is crucial for motor performance and longevity, reducing risks of electrical faults. Referencing official manuals and online forums can help troubleshoot common issues and optimize setups. Always follow safety guidelines when working with high-voltage systems. Understanding these diagrams is key for electricians and engineers to ensure reliable motor control systems.

1.1 Overview of 3 Phase Motor Starters

A 3-phase motor starter is a device used to control and protect induction motors during startup and operation. It ensures smooth acceleration, prevents voltage spikes, and safeguards against overloads or short circuits. Common types include Direct-On-Line (DOL) and Star-Delta starters, each suited for different applications; DOL starters are straightforward, connecting the motor directly to the power supply, while Star-Delta starters reduce starting current for large motors. These starters typically consist of contactors, overload relays, and circuit breakers. Their wiring diagrams provide clear connections for power, control, and safety circuits. Proper installation and configuration are essential for motor efficiency and longevity, making them indispensable in industrial environments. Understanding their operation and application is crucial for electricians and engineers to ensure reliable motor control systems.

1.2 Importance of Wiring Diagrams in Motor Control

Wiring diagrams are indispensable in motor control, offering a visual representation of electrical connections for 3-phase motor starters. They guide technicians through proper installation, ensuring components like contactors, overload relays, and circuit breakers are correctly linked. Clear diagrams prevent wiring errors, which can lead to motor damage or safety hazards. They also facilitate troubleshooting by pinpointing potential fault locations. Compliance with industry standards is ensured through accurate diagrams, reducing risks of electrical faults. Regular updates and adherence to manufacturer specifications are crucial, as seen in resources like the 3-phase-motor-starter-wiring.pdf. These documents highlight the importance of precise wiring for optimal motor performance and longevity, making them essential tools for engineers and electricians in industrial settings.

Understanding 3 Phase Motor Starters

3-phase motor starters are electro-mechanical devices designed to control and protect induction motors. They ensure smooth startup, stopping, and operation while protecting against overloads and short circuits. These starters are available in configurations like Direct-On-Line (DOL) and Star-Delta, each suited for specific applications. Proper understanding of their working principles is essential for safe and efficient motor control. They typically consist of contactors, overload relays, and circuit breakers, working together to manage motor power supply. Referencing wiring diagrams, like those in the 3-phase-motor-starter-wiring.pdf, helps in understanding their internal connections and operation.

2.1 Basic Concepts of 3 Phase Motor Starters

3-phase motor starters are essential for controlling and protecting three-phase induction motors. These starters manage the motor’s startup, stopping, and operation, ensuring protection against overloads and short circuits. Common types include Direct-On-Line (DOL) and Star-Delta starters, each suited for different applications. The DOL starter directly connects the motor to the power supply, while the Star-Delta starter reduces starting current by initially configuring the motor windings in a star pattern, then switching to a delta configuration once running. Understanding these concepts is crucial for interpreting wiring diagrams, such as those found in a 3-phase-motor-starter-wiring.pdf, which illustrate the connections between components like contactors, overload relays, and circuit breakers.

2.2 Working Principles of Motor Starters

Motor starters function by controlling the power supply to an electric motor, ensuring safe starting, stopping, and protection against overloads and short circuits. A 3-phase motor starter typically includes a contactor, overload relay, and circuit breaker. The contactor acts as an electrically controlled switch that connects and disconnects the motor from the power supply. The overload relay monitors the current flowing to the motor and trips if it exceeds a set threshold, protecting the motor from damage. The circuit breaker provides short-circuit protection, interrupting the circuit in case of a fault. These components work together to manage the motor’s power, ensuring smooth operation and protection. Wiring diagrams, such as those in a 3-phase-motor-starter-wiring.pdf, illustrate the connections and sequences for proper installation and functionality.

Components of a 3 Phase Motor Starter

A 3-phase motor starter consists of a contactor, overload relay, circuit breaker, and control circuit. These components work together to safely control and protect the motor.

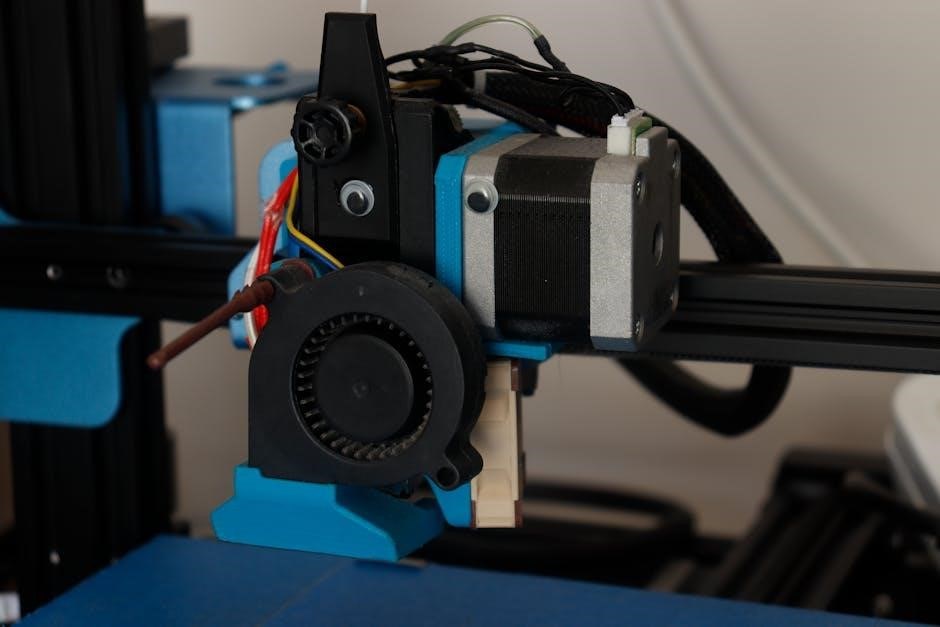

3.1 Motor Starter Components and Their Functions

A 3-phase motor starter comprises essential components that ensure safe and efficient motor operation. The contactor acts as the primary power-switching device, connecting and disconnecting the motor from the power supply. The overload relay protects the motor from overcurrent conditions by tripping during excessive load. A circuit breaker or fuse provides short-circuit protection, isolating the circuit in case of faults. The control circuit, including pushbuttons, pilot devices, and auxiliary contacts, regulates the motor’s start/stop operations. These components work together to provide reliable motor control, ensuring safety and preventing damage from electrical surges or overloads. Proper wiring of these elements, as shown in a 3-phase motor starter wiring diagram, is crucial for optimal performance and protection.

3.2 Circuit Breakers, Contactors, and Overload Relays

A 3-phase motor starter relies on circuit breakers, contactors, and overload relays for protection and control. Circuit breakers act as the primary protective device, interrupting the circuit in case of short circuits or overloads. Contactors are electromechanical switches that connect or disconnect the motor from the power supply, ensuring smooth operation during start/stop cycles. Overload relays monitor the motor’s current and trip if excessive current is detected, preventing damage from overloading. Together, these components provide a robust protection system, ensuring the motor operates safely and efficiently. Proper wiring of these devices, as illustrated in a 3-phase motor starter wiring diagram, is essential for their coordinated function and the overall system’s reliability.

Wiring Diagrams for 3 Phase Motor Starters

Wiring diagrams are essential for 3-phase motor starter installations, providing a visual guide for connecting components safely and efficiently. They ensure proper installation and operation.

4.1 Direct-On-Line (DOL) Starter Wiring Diagrams

DOL starter wiring diagrams provide a clear visual representation for connecting 3-phase motors directly to power lines. They include a contactor that acts as the main power switch, an overload relay to protect against overcurrent, and auxiliary contacts for control circuits. The motor terminals (U, V, W) are connected to the contactor’s output, while the control circuit uses a start/stop button to energize the contactor’s coil. Proper sizing of components ensures safe operation, and the overload relay is typically placed on the load side to monitor motor current effectively. Safety features like disconnect switches are recommended for isolation. Following the diagram step-by-step helps prevent electrical hazards and ensures the motor operates smoothly.

4.2 Star-Delta Starter Wiring Diagrams

Star-Delta starter wiring diagrams illustrate the connections for reducing voltage during motor startup. These diagrams show the motor windings connected in a star configuration initially, then switched to delta once running. The contactor and overload relay are essential components, with timers controlling the switching between star and delta modes. The control circuit includes a start button to initiate the sequence and a stop button to halt operation. Proper sizing of components ensures smooth operation, and the diagram highlights the need for correct phasing to avoid motor damage. Safety features like isolation switches are recommended for maintenance. Following the diagram ensures reduced starting current, minimizing stress on the motor and power supply, while maintaining efficiency and reliability in industrial applications.

Step-by-Step Installation Guide

Install the motor starter by preparing tools, connecting power supply, wiring control circuits, and testing functionality. Follow diagrams for accurate connections and ensure safety protocols are observed.

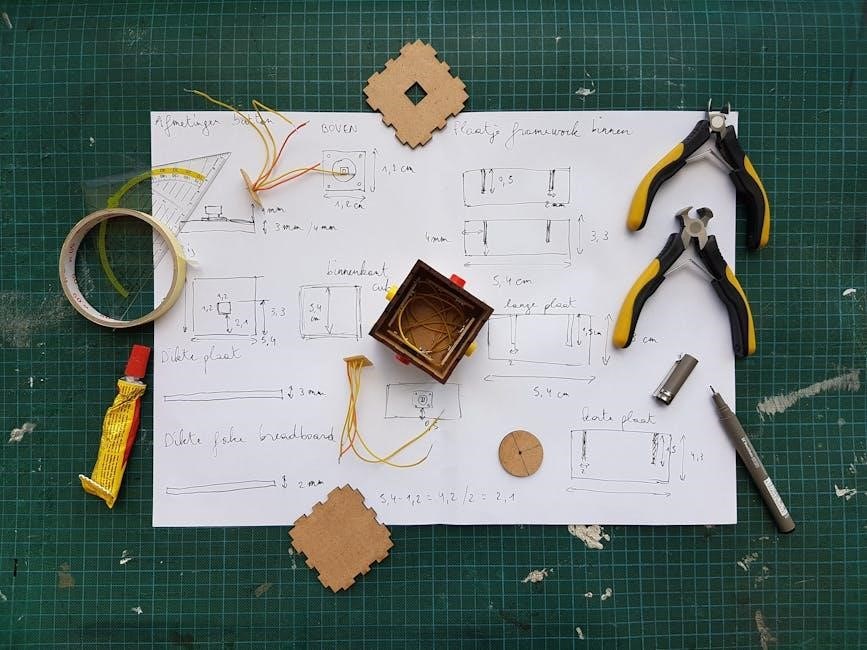

5.1 Preparing the Components and Tools

Begin by gathering all necessary components, including the motor starter unit, contactor, overload relay, circuit breaker, and control devices like pushbuttons and indicator lights. Ensure you have the appropriate power supply and motor cables. Tools needed include a multimeter, screwdrivers, pliers, wire strippers, and safety gear such as gloves and safety glasses. Refer to the wiring diagram PDF to identify and prepare all parts. Mount the starter in a suitable enclosure, considering environmental factors. Prepare control circuit wiring and connectors, ensuring they meet specifications. Organize all components and tools to streamline the installation process, minimizing delays and potential errors.

5.2 Connecting the Power Supply

Connect the power supply to the motor starter by following the wiring diagram PDF. Ensure the three-phase power supply lines (R, S, T) are correctly identified and connected to the starter’s input terminals. Verify the voltage rating matches the motor and starter specifications. Use appropriately sized cables to minimize voltage drop. Connect the neutral and earth wires as specified for safety. Ensure all connections are secure and tighten terminal screws properly. Double-check the phase sequence to avoid motor rotation issues. Use a multimeter to confirm voltage presence before energizing the circuit. Always de-energize the system before making or breaking connections to prevent electrical hazards. Properly route cables to avoid interference and ensure reliable operation.

5.3 Wiring the Control Circuit

Wiring the control circuit for a 3-phase motor starter involves connecting components like pushbuttons, indicators, and protection devices as shown in the wiring diagram PDF. Begin by identifying the control voltage, typically 24V or 220V, and ensure all devices are compatible. Connect the start and stop pushbuttons in series, with the stop button normally closed and the start button normally open. Use control wires to link these buttons to the contactor coil. Connect overload relays to protect the motor from overcurrent. Ensure proper grounding and use appropriately sized wires to minimize voltage drop. Follow the diagram to connect auxiliary contacts for maintaining the circuit when the start button is released. Test continuity with a multimeter and ensure all connections are secure before energizing the circuit; Always follow safety guidelines and de-energize the circuit before making any changes.

5.4 Testing the Motor Starter

Testing the motor starter is a critical step to ensure proper operation and safety. Begin by verifying that all connections are secure and match the wiring diagram PDF. Use a multimeter to check for continuity in control and power circuits. Apply the power supply and test the control circuit by pressing the start and stop buttons to ensure the contactor engages and disengages correctly. Observe the motor’s behavior to confirm smooth starting and stopping. Test the overload relay by simulating an overcurrent condition to ensure it trips as expected. Measure voltage at key points to ensure proper levels. Finally, inspect all components for signs of overheating or damage. Document any issues and address them before placing the system into service. Always follow safety protocols during testing to avoid electrical hazards.

Safety Considerations

Always wear protective gear like gloves and safety glasses. Ensure power is off before starting work. Use proper tools and follow industry standards to prevent electrical shocks and injuries.

6.1 Safety Precautions for Wiring

When working with 3-phase motor starter wiring, always ensure the power supply is disconnected to avoid electrical shocks. Use a multimeter to confirm voltage absence.

Wear personal protective equipment (PPE) such as insulated gloves and safety goggles to protect against arc flashes or sparks.

Follow proper lockout/tagout procedures to prevent accidental energization of the circuit.

Ensure all connections are secure and properly insulated to avoid short circuits.

Avoid overloading the circuit, as this can lead to overheating and fire hazards.

Keep the work area clean and well-lit to minimize tripping or accidental tool contact.

Never bypass safety devices like overload relays or circuit breakers.

Grounding the system correctly is essential to protect against electrical faults.

Always refer to the wiring diagram and manufacturer’s instructions for specific safety guidelines.

6.2 Best Practices for Motor Starter Installation

Always follow the manufacturer’s instructions and wiring diagrams for accurate installation.

Ensure the motor starter is sized correctly for the motor to prevent overheating and ensure efficiency.

Mount the starter on a sturdy, vibration-free surface in a cool, dry location.

Use high-quality cables and connectors to minimize resistance and heat buildup.

Secure all connections tightly to avoid loose wires, which can cause arcing or short circuits.

Install overload protection devices to safeguard the motor from overcurrent conditions.

Test the system at low voltage before full operation to verify proper function.

Regularly inspect and maintain the starter to ensure reliable performance.

Keep documentation and records of the installation for future reference.

Adhere to local electrical codes and standards for compliance and safety.

Troubleshooting Common Issues

Troubleshooting involves identifying issues like power supply problems, wiring faults, or component failures. Check for blown fuses, tripped breakers, or overheating due to overloads or connections.

7.1 Identifying Common Faults in Motor Starters

Common faults in 3-phase motor starters include blown fuses, tripped circuit breakers, or contactor failure due to overloads or short circuits. Faulty wiring, such as loose connections or incorrect phase sequencing, can prevent the motor from starting or cause it to run inefficiently. Overheating is another issue, often caused by overloaded motors or poor ventilation. Faulty overload relays may trip unnecessarily, while failed contactors can prevent the motor from engaging. Using a multimeter, check for open circuits, short circuits, or low insulation resistance in the wiring. Referencing a 3-phase motor starter wiring diagram can help pinpoint faults by verifying connections and ensuring proper phase alignment. Early detection of these issues is critical to prevent motor damage and ensure safe operation.

7.2 Resolving Wiring and Connection Problems

Resolving wiring and connection issues in 3-phase motor starters requires careful inspection and adherence to the wiring diagram. First, disconnect the power supply to ensure safety. Use a multimeter to check for short circuits, open circuits, or incorrect phase sequencing. Verify that all connections are tight and free from corrosion. If a contactor or overload relay is faulty, replace it with a compatible spare. Ensure the control circuit wiring matches the diagram, as mismatches can cause the starter to malfunction. Test the motor by bypassing the starter temporarily to isolate the issue. Referencing a 3-phase motor starter wiring diagram PDF can help confirm proper connections and phase alignment. Always follow safety protocols and manufacturer guidelines when troubleshooting and repairing motor starters to avoid further damage or hazards.

Applications and Variations

3-phase motor starters are widely used in industrial machinery, pumps, and manufacturing processes. Variations include DOL and Star-Delta starters, each suited for specific motor applications and power requirements.

8.1 Industrial Applications of 3 Phase Motor Starters

3-phase motor starters are extensively used in various industrial applications, including manufacturing, mining, and heavy machinery. They are essential for controlling motors in conveyor systems, pumps, and compressors. In the textile industry, they regulate spinning and weaving machines. HVAC systems rely on these starters for fan and compressor control. The oil and gas sector uses them for pumps and drilling equipment. Water treatment plants employ 3-phase starters for filtration and pumping systems. Construction sites utilize them for cranes and hoists. These starters ensure reliable motor operation, reduce voltage spikes, and protect equipment from overloads. Their versatility and durability make them indispensable in industrial settings, enhancing efficiency and safety in motor-driven applications.

8.2 Specialized Motor Starter Configurations

Specialized motor starter configurations are designed to meet specific industrial requirements. One common type is the soft starter, which reduces voltage during motor startup to minimize inrush current and mechanical stress. Another configuration is the variable frequency drive (VFD), which allows speed adjustment by controlling the motor’s frequency and voltage. Additionally, some starters incorporate motor protection circuits (MPCs) with advanced features like ground fault protection and arc flash mitigation. Custom configurations may include remote monitoring and control, enabling operators to manage motors from a central location. These specialized setups are tailored for high-performance, high-reliability applications, ensuring optimal motor operation in demanding environments while adhering to safety and efficiency standards.

References and Resources

Official documentation, including IEC and NEMA standards, provides detailed guidelines. Online forums like Electrical Engineering Stack Exchange offer practical advice. Refer to manufacturer manuals and wiring diagram PDFs for specific configurations and compliance.

9.1 Official Documentation and Manuals

Official documentation and manuals are essential for understanding and implementing 3-phase motor starter wiring diagrams. These resources, often provided by manufacturers like Siemens, ABB, and Allen-Bradley, include detailed schematics, component specifications, and installation guidelines. IEC (International Electrotechnical Commission) and NEMA (National Electrical Manufacturers Association) standards are critical for ensuring compliance with safety and performance requirements. Wiring diagram PDFs are widely available online, offering step-by-step instructions for direct-on-line (DOL) and star-delta configurations. These manuals also cover troubleshooting, maintenance, and compatibility with variable frequency drives (VFDs). Always refer to the specific motor starter model’s documentation to ensure accurate and safe wiring practices.

9.2 Online Forums and Communities for Support

Online forums and communities are invaluable resources for troubleshooting and understanding 3-phase motor starter wiring diagrams. Platforms like Reddit’s r/ElectricalEngineering and r/AskElectrical offer peer-to-peer advice from experienced professionals. Websites such as All About Circuits and ElectriciansForums.com provide detailed discussions, tutorials, and downloadable resources, including PDF guides for motor starter wiring. These communities often share real-world experiences, tips, and solutions for common issues like incorrect wiring or overload relay setups. Many forums also host experts who can interpret complex diagrams and offer tailored advice. Engaging with these communities ensures access to diverse perspectives and up-to-date information, making them a crucial supplement to official documentation.